About Me

Hi, I’m John Remus-Everitt, owner and operator of M3 Custom Metal Design. I started this business as a side hustle to help prepare myself for retirement from my career as a high school teacher in southern Alberta. Over time, my passion for metalworking and design grew, and what began as a way to keep busy after teaching evolved into a full-fledged business.

I've always been fascinated by how machines and humans can work together to make tasks more efficient. This curiosity has driven me to constantly explore new ways to combine creativity with technology. As a lifelong learner, I run the Academy of Mechatronics, where I’ve gained the skills to use computer software to create custom designs. I also teach the Fabrication program, continuously refining my ability to bend, fuse, and manipulate metal into unique, functional works of art.

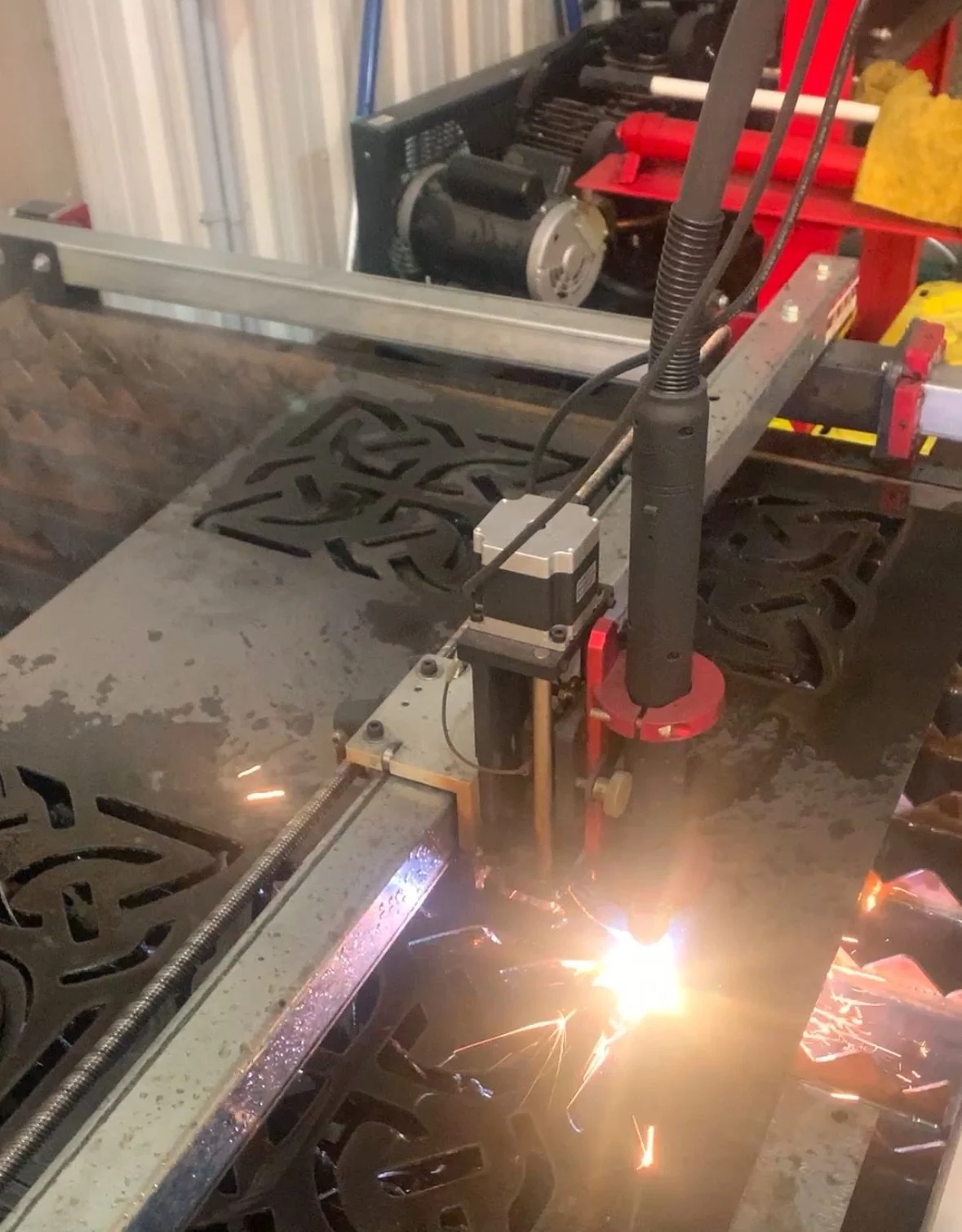

I work with a Langmuir Crossfire Pro CNC plasma table and a Hypertherm Powermax 65 Synx plasma cutting machine, both of which allow me to deliver precise and high-quality cuts for each custom project.

At M3 Custom Metal Design, I get to put my creative brain to work by designing, cutting, and finishing unique projects for my clients. Whether it's a custom piece for your home, a sign for your business, or a special gift, I’m passionate about bringing your vision to life with expert craftsmanship and attention to detail.

Let’s create something extraordinary together!

About the Equipment

To ensure the highest quality and precision, we use top-of-the-line equipment:

Fusion 360 (CAD Software)

Fusion 360 is an advanced, cloud-based Computer-Automated Design (CAD) software used to create detailed 3D models for custom metal projects. This software allows us to design your project with incredible accuracy, simulate and test it digitally, and generate the precise toolpaths needed for machining. Fusion 360 provides seamless integration between design, engineering, and manufacturing, making it the ideal tool for bringing your vision to life.

Crossfire Pro CNC Table

This machine features a custom 4' X 3.5' water table that helps to capture metal fragments and reduce airborne debris during cutting, ensuring a cleaner and safer workspace.

Plasma Cutter - Hypertherm Powermax 65 SYNC

Our Hypertherm Powermax 65 SYNC plasma cutter can cut up to 5/8" thick cold rolled steel with precision. For thinner materials (under 14 gauge), we utilize Finecut 45 amp tips, allowing for finer, more detailed cuts.

Larger Projects

If your design exceeds the size of the CNC cutting area, we can seamlessly weld the pieces together to meet your required dimensions. Whether it's a single custom piece or a large, multi-part project, we ensure each element meets your expectations.

We’re dedicated to turning your vision into a reality with the highest quality materials, advanced Fusion 360 CAD design, and expert craftsmanship. Reach out today to start your custom metal project!